Antibody production

Antibody production

Ensuring Monoclonality in Therapeutic Antibody Production with VIPS Technology

Therapeutic antibodies have transformed the treatment landscape for various diseases, including cancer, autoimmune disorders, and infectious diseases. The journey to produce these powerful antibodies involves several crucial steps, beginning with generating antigen-specific antibodies and leading to the development of stable cell lines that produce these antibodies with high yield and consistent quality. A key step in this process is clone selection, where individual cells that produce the desired antibody are isolated, and custom cell lines are established from these clones. The main goal here is to identify the most productive and stable clones to ensure the effectiveness of the therapeutic antibody. The importance of clone selection cannot be overstated, as the quality and productivity of the final antibody product hinge on the characteristics of the selected clones. Efficient and accurate clone selection can reduce production costs, improve product consistency, and speed up development timelines. This is where Verified In-Situ Plate Seeding (VIPS) technology comes into play. VIPS represents a breakthrough in the clone selection process, automating the precise seeding and verification of single cells into microplate wells, and ensuring accurate monoclonality. By combining automated cell dispensing with real-time imaging, VIPS significantly boosts the efficiency, accuracy, and reproducibility of clone selection. This innovative technology minimizes the risk of manual errors, reduces the number of selection rounds required, and accelerates the overall development timeline, making it an essential tool in therapeutic antibody production.This blog post serves as a comprehensive guide to understanding how VIPS technology accelerates stable cell development and enhances the therapeutic antibody manufacturing process. By guaranteeing efficient single-cell seeding with image-based proof of clonality, VIPS significantly reduces development time by over 50% and provides clonality reports crucial for successful IND submissions. These advancements pave the way for groundbreaking therapies and life-saving innovations.

- Introduction to Verified In-Situ Plate Seeding (VIPS) Technology

- What is Verified In-Situ Plate Seeding?

- VIPS Workflow Overview

- Key Features and Advantages of VIPS

- High Efficiency and Gentle Seeding

- Double Lock of Clonality Assurance

- Advanced Artificial Intelligence (AI) Integration

- Regulatory Compliance

- Sterility

- Compatibility with Cell Growth Supplements

- Challenges in Traditional Clone Selection

- Labor-Intensive and Time-Consuming Processes

- Manual Screening and Clone Selection Bottlenecks

- Multiple Rounds of Selection and Validation

- Variability and Inconsistency

- Issues with Random Integration and Expression Variability

- Challenges in Identifying High-Producing Clones

- High Costs and Resource Intensiveness

- Financial and Material Resources Required for Traditional Methods

- Impact on Overall Production Timelines

- Conclusion

- ProteoGenix’s Custom Cell Line Development Services

- Reference

Introduction to Verified In-Situ Plate Seeding (VIPS) Technology

What is Verified In-Situ Plate Seeding?

Verified In-Situ Plate Seeding (VIPS) is a cutting-edge technology, dedicated to revolutionizing the clone selection process in therapeutic antibody production. VIPS automates the precise seeding and verification of single cells into 96 and 384 well microplates, ensuring each well receives exactly one cell, a critical factor for accurate clone selection and monoclonality assurance.

The VIPS system integrates single-cell deposition with simultaneous in-situ image verification, enhancing the efficiency and reliability of the clone screening process. This innovative bench-top instrument, designed for placement inside a standard biological safety class 2 hood, utilizes interchangeable and sterilizable components to maintain strict sterility throughout the process.

Single-cell cloning is a foundational technique in cell biology, essential for isolating and propagating cells with specific genetic attributes. This process is not only crucial for fundamental research, allowing scientists to study cellular properties in controlled settings, but also indispensable in the biopharmaceutical industry. Here, cell substrates must exhibit reproducible characteristics to ensure the performance and safety of therapeutic antibody products through homogenous cell populations.

VIPS Workflow Overview

This workflow will take you through the key steps of using Verified In-Situ Plate Seeding for single-cell seeding and clone selection.

- Preparation of Cell Suspension: The process begins with the preparation of a cell suspension containing the cells of interest expressing the therapeutic antibody. The concentration of the cells is carefully adjusted to ensure optimal seeding efficiency.

- Automated Single-Cell Seeding: The VIPS system automatically dispenses single cells into individual wells of a 96 or 384-well microplate. This is done using a gentle deposition process to maintain cell viability while a magnetic stirrer will keep the cells in suspension in the VIPS reservoir.

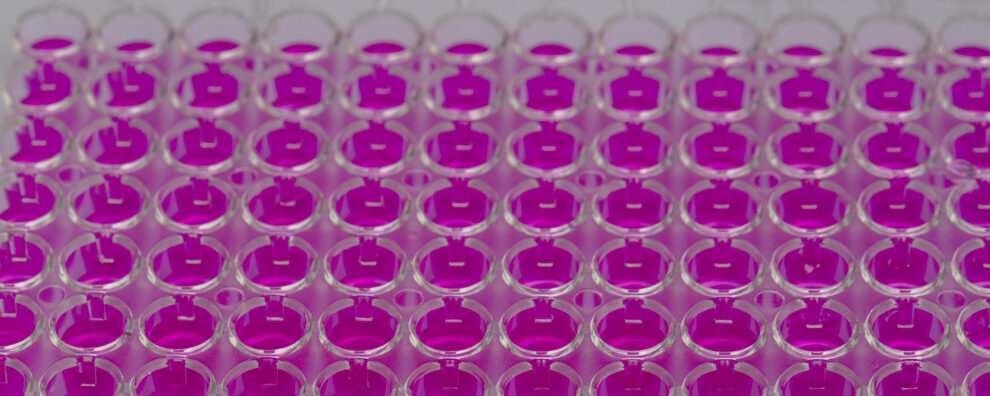

- Simultaneous In-Situ Image Verification: Immediately after seeding, VIPS captures high-resolution images of each well to verify the presence of a single cell. This step, ensures that only wells containing a single cell are identified and recorded.

- Real-Time Imaging and Monitoring: The system continuously monitors the wells at regular intervals to track the growth and development of the seeded cells. This real-time imaging helps in confirming monoclonality and assessing the viability of the clones.

- Data Integration and Analysis: The imaging data is integrated with a data management system that tracks and records the seeding outcomes. This ensures data continuity and integrity, facilitating downstream analysis and reporting.

- Clonal Expansion and Selection: Once the single cells have been seeded and verified, they are allowed to grow and expand into clonal populations. The VIPS system continues to monitor these clones, capturing images at multiple time points to document their growth.

- Quality Control and Validation: Throughout the process, the VIPS system performs continuous quality control checks to ensure the accuracy and reproducibility of the seeding and cloning process. This includes statistical validation of the seeding protocol and ongoing quality control measures.

- Reporting and Documentation: The VIPS system generates detailed reports that include images and data on the seeding and growth of each clone. These reports can be used for regulatory submissions and to demonstrate compliance with guidelines such as ICH Q5D and EMA/CHMP.

Key Features and Advantages of VIPS

Verified In-Situ Plate Seeding technology offers numerous advantages that significantly enhance the efficiency and reliability of the single-cell seeding and clone selection process. It combines high-efficiency seeding, advanced AI-driven analysis, robust data management, and stringent regulatory compliance.

High Efficiency and Gentle Seeding

- Gentle Seeding Process: VIPS employs a low-pressure dispensing mechanism to minimize mechanical stress on cells during seeding. This gentle approach ensures cells remain intact and viable, crucial for their subsequent growth and the productivity of therapeutic antibodies. Unlike traditional methods like Limiting Dilution Cloning (LDC), which can be harsh and lead to high levels of cell stress and death, VIPS maintains cell quality and viability.

- Optimized Nozzle Design: The system’s nozzle is optimized for droplet formation and seeding efficiency, making it suitable for various cell types, including CHO, HEK, and iPSC cells. This design ensures optimal cell handling, reducing the likelihood of cell damage and enhancing overall seeding efficiency.

Double Lock of Clonality Assurance

- High-Resolution Z-Stack Imaging: VIPS captures twenty high-resolution Z-stack images immediately after seeding. These images provide a comprehensive view of each well, verifying the presence of a single cell. This process, ensures only wells with a single cell are identified and tracked, significantly reducing the risk of errors and providing robust proof of clonality. VIPS significantly improves upon traditional single-cell seeding methods like Limiting Dilution Cloning (LDC), which are often labor-intensive and time-consuming. The real-time, high-resolution imaging of each well immediately after cell deposition ensures a high occupancy of single cells in wells, dramatically increasing seeding efficiency and reliability.

- Day 0 Evidence: The system captures both initial droplet images and whole-well images on Day 0. This double-lock assurance provides definitive evidence of clonality, essential for regulatory submissions and quality control. The images are documented and included in the Clonality Report, which can be directly used for IND submissions.

Advanced Artificial Intelligence (AI) Integration

- AI-Driven Analysis: VIPS employs a proprietary AI-driven algorithm to differentiate between single cells, cell aggregates, debris, and air bubbles. This advanced image analysis ensures accurate identification and documentation of single cells. The AI capabilities are integrated with a software platform, which manages data analysis, sample tracking, and error reduction, enhancing the overall reliability of the seeding process.

Regulatory Compliance

- Clonality Report: The VIPS system excels in providing robust documentation through its Clonality Report, which meticulously details the entire seeding process from single-cell deposition to colony formation. This comprehensive report captures high-resolution images and data at various stages, ensuring a transparent and traceable record of each step. The Clonality Report is crucial for regulatory submissions, as it meets the stringent guidelines set forth by authorities such as the FDA’s 21 CFR Part 11 and the EMA/CHMP. By offering definitive proof of clonality, VIPS ensures that the documentation supports compliance, thereby simplifying and streamlining the regulatory approval process.

- Comprehensive Data Management: In the process of cell seeding and clone development, managing and analyzing the extensive data generated is crucial. Advanced software tools offer robust capabilities for data analysis, error reduction, and sample tracking. These tools provide a detailed audit trail that records every step of the workflow, which is essential for meeting stringent regulatory requirements. By ensuring that all data is securely stored, easily accessible, and well-organized, the integration of such software facilitates a smooth and efficient regulatory review process.

Sterility

- Optimized for Sterility: The design of the VIPS system allows it to be placed inside a standard biological safety class 2 hood, maintaining a sterile environment throughout the seeding process. This is crucial for preventing contamination and ensuring the integrity of the cell lines. Also, the use of single-use, gamma-irradiated seeding kits eliminates the risk of sample carryover and contamination, ensuring a sterile environment for cell processing.

Compatibility with Cell Growth Supplements

- Enhanced Cloning Efficiency: VIPS can be combined with various cell growth supplements to enhance cloning efficiency and cell survival. For example, the combination of VIPS with InstiGRO™ supplements has shown significant improvements in the number of colonies growing in each plate, accelerating the overall cell line development process.

- Optimal Growth Conditions: The system automatically fills wells with culture media after seeding, providing the necessary nutrients for cell survival and proliferation. This automated media filling not only saves time but also ensures each cell has the best possible start, further enhancing viability and productivity.

Challenges in Traditional Clone Selection

The development of therapeutic antibodies is a complex and multifaceted process that relies heavily on the efficient and accurate selection of high-producing clones. Traditional methods of clone selection, however, present several significant challenges that can hinder productivity and efficiency. These challenges include labor-intensive and time-consuming processes, variability and inconsistency in results, and high costs and resource intensiveness.

Labor-Intensive and Time-Consuming Processes

Manual Screening and Clone Selection Bottlenecks

One of the primary challenges in traditional clone selection is the manual nature of the screening and selection processes. Researchers often rely on techniques such as Limiting Dilution Cloning (LDC) and Semi-Solid Media Cloning to screen thousands of potential clones to identify those with the highest productivity. These methods involve multiple steps, including the isolation of single cells, expansion, and initial screening for productivity, each requiring significant human intervention. This manual process is labor-intensive and prone to human error, which can lead to inconsistencies in the data and potentially overlook high-producing clones. Moreover, the sheer volume of clones that need to be screened can be overwhelming, making it difficult for researchers to maintain accuracy and efficiency throughout the process.

Studies have demonstrated that VIPS outperforms traditional LDC methods by producing 6-8 times more clones of single-cell origin, particularly in Chinese Hamster Ovary (CHO) cell lines. VIPS’s ability to accurately identify single-cell and multiple-cell seeded wells with an accuracy range of 65-81% underscores its precision and effectiveness in accelerating cell line development workflows.

Further complicating the clone selection process, methods like Fluorescence-Activated Cell Sorting (FACS) and Microfluidic Systems have been employed to improve the isolation of single cells. While FACS uses fluorescent markers to sort and isolate cells based on specific characteristics, and microfluidic systems use micro-scale channels to manipulate and sort cells, both still require significant manual intervention for downstream processing and validation. These techniques, though more advanced, still demand careful handling, setup, and maintenance, introducing variability and errors.

The reliance on these manual and semi-automated techniques not only slows down the overall process but also increases the likelihood of variability and inconsistency in clone selection. This is particularly problematic when scaling up from small-scale experiments to larger production runs, as minor inconsistencies at the early stages can have significant downstream effects.

Multiple Rounds of Selection and Validation

Traditional clone selection methods often require multiple rounds of selection and validation to ensure that the chosen clones are stable and high-producing. This iterative process can be extremely time-consuming, as each round may take several weeks or even months to complete. During each round, researchers must culture the cells, perform assays to measure productivity and validate the results. The need for multiple rounds arises from the inherent variability in clone productivity, as clones that initially appear to be high producers may lose productivity over time, necessitating further rounds to identify stable clones.

Variability and Inconsistency

Issues with Random Integration and Expression Variability

One of the major sources of variability in traditional clone selection is the random integration of the transgene into the host cell genome. This randomness can lead to significant differences in gene expression levels among clones, even if they originate from the same transfection event. Expression variability can also be influenced by factors such as the site of integration and the copy number of the transgene. This makes it challenging to predict which clones will exhibit stable and high levels of antibody production over time. As a result, researchers must invest significant time and resources in screening and validating a large number of clones to identify those with consistent and high productivity.

Challenges in Identifying High-Producing Clones

The variability and inconsistency in gene expression levels make it difficult for researchers to accurately identify high-producing clones. Traditional methods often rely on initial screening assays that may not accurately reflect the long-term productivity of the clones. Clones that show high productivity in early assays may not maintain that level of productivity as they are expanded and cultured over time. This challenge is compounded by the fact that traditional screening methods may not be sensitive enough to detect subtle differences in productivity among clones. Consequently, researchers may overlook potentially high-producing clones, leading to suboptimal selection outcomes. The inability to accurately identify high-producing clones on time can significantly delay the overall process of therapeutic antibody development.

High Costs and Resource Intensiveness

Financial and Material Resources Required for Traditional Methods

Traditional clone selection methods are not only time-consuming but also resource-intensive. The need for multiple rounds of selection and validation, coupled with the high volume of clones that need to be screened, requires substantial financial and material resources. Researchers must invest in a variety of reagents, culture media, and laboratory equipment to carry out the screening and selection processes.

Impact on Overall Production Timelines

The labor-intensive, time-consuming, and resource-intensive nature of traditional clone selection methods can have a significant impact on overall production timelines. The need for multiple rounds of selection and validation, coupled with the variability and inconsistency in clone productivity, can lead to delays in the development process. Extended production timelines can also have financial implications, as they increase the overall cost of development and reduce the return on investment for pharmaceutical companies. Delays in bringing therapeutic antibodies to market can result in lost revenue opportunities and reduced competitiveness in the market.

The challenges associated with traditional clone selection methods are significant and multifaceted. Labor-intensive and time-consuming processes, variability and inconsistency in results, and high costs and resource intensiveness can all hinder the efficiency and productivity of therapeutic antibody development. These bottlenecks emphasize the need for more advanced and reliable methods of clone selection that can address these challenges and streamline the development process.

Verified In-situ Plate Seeding (VIPS) technology offers a promising solution, providing researchers with a more efficient, consistent, and cost-effective method of clone selection process in therapeutic antibody development. By automating key aspects of the process, VIPS reduces the manual labor required, minimizes variability, and ensures a higher degree of consistency in results. This technological advancement not only speeds up the clone selection process but also enhances the overall productivity of therapeutic antibody development.

Conclusion

Verified In-Situ Plate Seeding (VIPS) technology represents a transformative advancement in the clone selection process for therapeutic antibody production. By automating the precise seeding and verification of single cells, VIPS enhances the efficiency, accuracy, and reproducibility of the clone selection process. This innovative technology minimizes the risk of manual errors, reduces the number of selection rounds required, and accelerates the overall development timeline, making it an essential tool for modern biopharmaceutical manufacturing. VIPS significantly improves upon traditional methods, ensuring that the quality and productivity of therapeutic antibodies are optimized, which ultimately benefits patients by delivering high-quality treatments more quickly and efficiently.

ProteoGenix’s Custom Cell Line Development Services

ProteoGenix offers an unparalleled custom cell line development service, designed to meet the diverse needs of researchers and pharmaceutical companies. Utilizing advanced VIPS™ technology, ProteoGenix accelerates custom cell line projects by over 50%, providing high-resolution verification and ensuring precise monoclonality. This efficiency not only speeds up your project timelines but also enhances the reliability and consistency of the results, making it an invaluable asset in therapeutic antibody production.

By selecting ProteoGenix, you gain access to extensive expertise, proprietary technologies, and client-focused services tailored to your specific project requirements. With a proven history of developing over 1500 proteins and 5000 antibodies, our comprehensive knowledge ensures top-tier service and support throughout your cell line development process. We provide IP-free cell lines, thorough stability studies, and detailed regulatory documentation to facilitate a smooth transition from research to large-scale production.

Our expert team collaborates with you to customize solutions that address your unique needs, from clone selection and growth condition optimization to production scaling and regulatory compliance. Our flexible and all-encompassing approach is designed to streamline workflows, reduce costs, and boost project efficiency.

So, are you prepared to enhance your antibody production ?

Let’s collaborate for cutting-edge custom cell line development for therapeutic antibody production. Explore our dedicated service pages to learn more !

Book a call with our experts today to discuss your project needs!

Reference

Han, C. L., et al. “Efficient Generation of Monoclonal Antibodies Using a Novel Platform Combining Single-Cell Cloning and High-Throughput Screening.” bioRxiv, 3 June 2022, https://doi.org/10.1101/2022.06.03.494661.